Bengaluru’s garment sector has a big Covid tear, Retail News, ET Retail

BENGALURU: The adverse effect of Covid-19 on India’s attire and textile business is beginning to demonstrate in Bengaluru, the country’s biggest textile manufacturing hub that employs about two.5 lakh workers. Many of the hugely employment-intensive outfits units in and all-around the town are both shutting down their operations or laying off workforce, even as Karnataka is limping again to normalcy from the Covid-induced lockdown.

BENGALURU: The adverse effect of Covid-19 on India’s attire and textile business is beginning to demonstrate in Bengaluru, the country’s biggest textile manufacturing hub that employs about two.5 lakh workers. Many of the hugely employment-intensive outfits units in and all-around the town are both shutting down their operations or laying off workforce, even as Karnataka is limping again to normalcy from the Covid-induced lockdown.

On Saturday, about 1,two hundred workers of a manufacturing unit device in Srirangapatna affiliated to the biggest attire manufacturer and exporter, Gokaldas Exports, have been laid off. The business has told the workers that they would be presented a part of the income for the following two weeks. The garment workers’ union is predicting closure of the manufacturing unit inevitably. At minimum four outfits manufacturing units in Bengaluru, of Backyard Metropolis Style, Sonal Garments, Texport Industries and Punith Creations, have shut their operations or laid off 50 percent their workforce in the past two-3 weeks, according to the workers’ union and business insiders. Many factories are anticipated to tread the very same route.

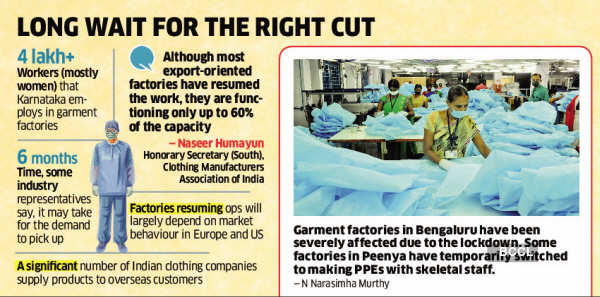

Garment factories in Karnataka employ additional than 4 lakh workers, typically females, and the uncertainty and layoffs are likely to have an impact on countless numbers of households who are dependent the business for livelihood.

Some of the business reps ET spoke to explained it may possibly take at minimum six months for desire to choose up. Since a substantial quantity of Indian outfits firms source goods to abroad buyers, the factories resuming operations in full scale will largely count on the market behaviour in Europe and the US.

“There are worries generally pushed by close-person desire. Most of the suppliers overseas are just about reopening and it is quite early to see how the desire will choose up. There is an apprehension that the financial disaster may perhaps drive buyers to be conservative. There could be additional desire for minimal-value garments than higher-value outfits,” explained the CEO of a top cloth manufacturing business, who did not want to be named.

In the meantime, some firms are earning changes to their solution traces as they resume operations.

At Mandhana Industries in Peenya industrial spot that employs about 1,000 workers, 50 percent the workforce is again at function. Like many other garment units, Mandhana as well has quickly switched to earning PPEs that incorporate facemask for top models like Wildcraft, and full body fits. “We will resume operations in full scale when we get new orders from our buyers abroad,” explained normal manager Rajashekhar Murthy M.

The business managed to export 20,000 pieces of outfits to Sweden and Spain through the lockdown, but export cost has now increased, Murthy explained, as the pandemic has affected air and sea freight companies as well, driving up tariffs. “Earlier, the cargo expenses have been 140 for every kg, but it has doubled now. Also, our buyers are inquiring for a thirty% price cut due to the fact of the falling desire across the world. It is not viable,” he explained.

The business is hoping to get some visibility on the market in six months. “We can’t predict how shortly the desire will improve. But, hopefully we will get an thought about the market revival in the following six months,” explained Naseer Humayun, the honorary secretary (south) of the Clothing Companies Association of India.