PCMC’s saw uses predictive maintenance to reduce downtime

06

Apr ’20

Pic: PCMC

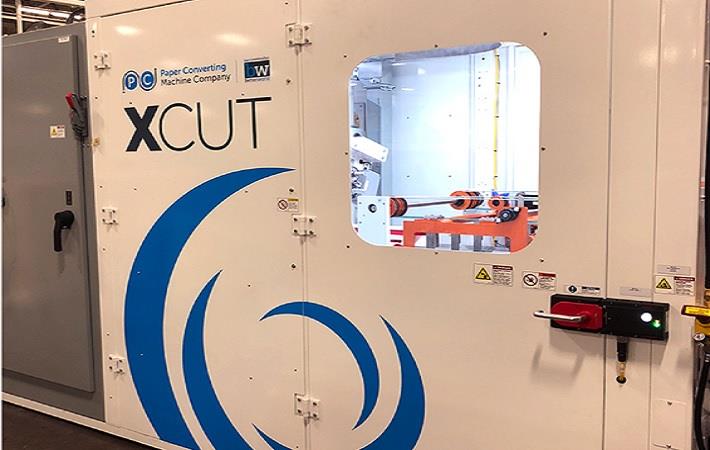

Paper Changing Machine Firm (PCMC), portion of Barry-Wehmiller, has introduced that the Xcut saw, its newest tissue log saw, now has the means to use predictive maintenance to cut down unplanned downtime. PCMCA manufactures superior-efficiency converting machinery for the tissue, nonwovens, package deal-printing, and bag-converting industries around the world.

With this new capability, operators will be in a position to monitor the lifecycles of vital parts and keep track of the efficiency of some others. The saw will provide notifications relating to forthcoming maintenance necessities ahead of they turn into vital concerns, allowing for operators to have alternative areas completely ready when the time comes, in accordance to PCMC.

The Xcut saw will keep track of and gather info from servo motor feed-back, vibration sensors and other units, and notify operators when the device requires maintenance. For case in point, if an axis becomes extra difficult to flip or experiences irregular vibrations, the predictive maintenance process will provide an notify that the gearbox may perhaps need to be replaced.

This multifaceted method to predictive maintenance enables operators to tackle various maintenance responsibilities at the similar time, which decreases downtime and receives the device again into manufacturing extra swiftly. “We want to give operators extra manage of their downtime. Predictive maintenance makes consciousness in advance of time and allows operators plan in advance,” Jonathon Zahn, PCMC’s guide mechanical engineer for the Xcut reported.

Fibre2Fashion News Desk (GK)

Paper Changing Machine Firm (PCMC), portion of Barry-Wehmiller, has introduced that the Xcut saw, its newest tissue log saw, now has the means to use predictive maintenance to cut down unplanned downtime. PCMCA manufactures superior-efficiency converting machinery for the tissue, nonwovens, package deal-printing, and bag-converting industries around the world.